Screw Conveyors & Dischargers

Conveying and elevating equipment for a diverse range of materials from foods and fine chemicals to biomass, aggregates and waste.

Product Types

Conveying and elevating equipment for a diverse range of materials from foods and fine chemicals to biomass, aggregates and waste.

GTX Screw Dischargers

GTX Tubular Screw Conveyor

GTX U-Trough Screw Convyor

What is a Screw Conveyor

The Guttridge screw conveyor, auger screw conveyor and screw discharger range is a versatile collection of machines designed to move all sorts of materials. Thanks to the simple design of a screw type conveyor, they’re suitable for many different materials, from abrasive stuff like sand and gravel to sticky substances like asphalt and clay. The way a conveyor screw works is pretty straightforward: a central auger rotates within a tube or trough, pushing the material along the length of the machine.

With over 50 years of experience, Guttridge has been designing and installing screw conveyors in a wide variety of industries, even creating bespoke screw conveyor systems for highly specialised applications. We also make a range of screw dischargers. These use one or more screws arranged side-by-side to take product out of a bin or hopper and move it into other downstream machinery.

If you need a hand picking the right screw conveyor for your specific application, we’re always here to help. Just get in touch with us using the online contact form or give us a call today.

Design Options

Here at Guttridge, we offer many different design options based on what you need your conveyor to do.

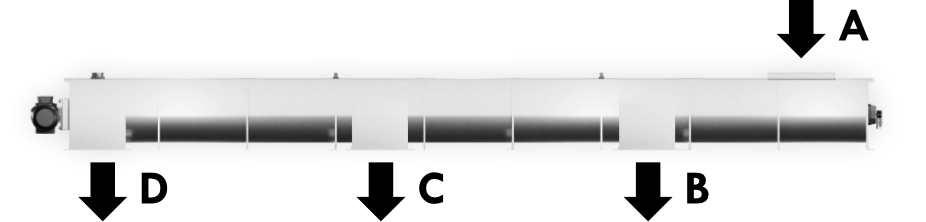

Most applications use a simple ‘A to B’ configuration, where material is fed in at one end and pushed by the auger to the other. But we can also provide machines with intermediate outlets, controlled by slide valves, to direct material from A to B, C, or D.

Another great option is a reversing screw conveyor. These are often fed from the centre, and a control system lets you send material in either direction depending on the way the auger is rotating. This can even be combined with intermediate outlets to give you even greater control over the feed.

Finally, we offer contra-rotating screw conveyors. These have a single auger where the flighting reverses at the centre. This clever design lets material flow towards the middle of the machine, no matter which end it’s fed from, making it ideal for combining multiple inputs into a single output.

For most customers, these flow options are the biggest decision to make when building a bulk handling system, and the team at Guttridge is always happy to help you make the right choice for your application.

We also offer many other design choices to get the perfect machine for you, including but not limited to:

- ATEX options

- Bearing configurations based on servicing requirements or application type

- Wear-resistant liners for the casings

- Various drive options

- Materials and finishes, such as stainless steel, galvanised steel, or specific paint and colour finishes

- Flighting type, which is usually selected in consultation with Guttridge to find the best type for the material you are conveying

- Various safety and operation sensors

- Special high or low temperature environments

‘A to B’ Configuration

‘Reversing Screw’ Configuration

Intermediate Outlets

‘Contraflow’ Configuration

Materials & finishes

We offer a range of finishes for our screw conveyors, with the choice often depending on the product being handled. We can also provide a painted finish to match specific safety or branding requirements.

Our available finishes include:

- Mild Steel: This is our standard finish, which is painted to protect against rust and corrosion. We can paint to any specified RAL colour, and specialist paint systems are also available for specific applications.

- Galvanised Steel: For superior corrosion resistance, galvanising is a great option, especially for applications where a painted finish is not suitable.

- Stainless Steel: We offer stainless steel with a range of surface finishes, from a standard plain finish to highly polished surfaces. This includes various Ra finishes for specific hygiene standards, and also electropolishing for an ultra-smooth, sterile finish.

“We were impressed with the company’s willingness to innovate new solutions that would help us to achieve the very highest levels of reliability – a major goal for our site.”

– Mr Adam Elmes, Project Manager at Lafarge, discussing the supply of sand/cement/aggregate handling equipment

Address

Guttridge Limited, Wardentree Park, Spalding, Lincolnshire, PE11 3UU, United Kingdom

Phone